High-Performance Xenon Flash Tubes for Stroboscopic, Warning & Industrial Applications

Reliable, High-Intensity Light Source for Precision Measurement, Safety, and Professional Use

Overview

We specialize in producing high-quality xenon flash tubes in various shapes, including linear, U-shaped, spiral, and circular designs, engineered for demanding applications across industries such as stroboscopic measurement, traffic and industrial warning lights, professional photography, aviation, scientific instruments, and more. These flash tubes provide high-intensity light output, fast response, and long lifespan, ensuring consistent performance even in extreme environments.

With over 25 years of manufacturing experience, we offer a reliable and cost-effective lighting solution for professionals worldwide, including lighting manufacturers, research institutes, laboratories, universities, and global wholesalers and retailers.

Core Product Features

Extremely Intense & Stable Light Output

White / Blue-White Light: Provides broad spectrum, ideal for freezing high-speed motion and ensuring accurate measurements.

High Peak Luminous Intensity: Ensures clear motion freezing for precise analysis.

Flash-to-Flash Consistency: Delivers reliable performance across multiple flashes, maintaining accuracy.

Fast Response for High-Speed Measurement

Microsecond to Millisecond Pulse Duration: Perfect for applications requiring rapid flashes, such as RPM measurement and vibration analysis.

Ideal for Motion Detection: Ensures precise measurement and inspection of high-speed motion.

Long Lifetime – Reduced Replacement Costs

≥ 10,000,000 Flashes: Designed for long operational life, significantly reducing maintenance and replacement costs.

Stable Electrode Structure: Optimized design ensures continuous operation for extended periods.

Wide Voltage Compatibility

Trigger Voltage: 2 kV – 10 kV.

Operating Voltage after Ionization: 200V – 600V, ensuring compatibility with most stroboscope power supplies.

Why Choose Xenon Flash Tubes?

Unmatched Peak Intensity

Xenon flash tubes can produce extremely high peak luminous intensity in a fraction of a millisecond, reaching megacandela (Mcd) levels. This intense pulse of light ensures superior visibility in fog, rain, snow, or even bright sunlight, making them ideal for emergency and industrial applications.

Simple Optics

The near-point-source characteristic of xenon flash tubes allows designers to use basic reflectors to achieve uniform 360° light coverage, making the design simpler and more cost-effective compared to LED systems, which require complex arrays and lenses.

Cost-Effective

Xenon flash tubes offer lower total costs than high-power LED arrays because they don’t require expensive heat dissipation systems or complex optical designs to achieve similar peak brightness.

Material Options – Tailored to Different Market Needs

Industrial Quartz / Fused Silica (Germany Origin)

High Thermal Resistance: Suitable for high-temperature environments.

Excellent UV Transmission: Ideal for professional, scientific, and heavy-duty applications.

Borosilicate Glass (Economic Solution)

Cost-Effective: Stable performance for standard industrial applications, making it perfect for budget-conscious projects.

Fully Customizable Designs (OEM Supported)

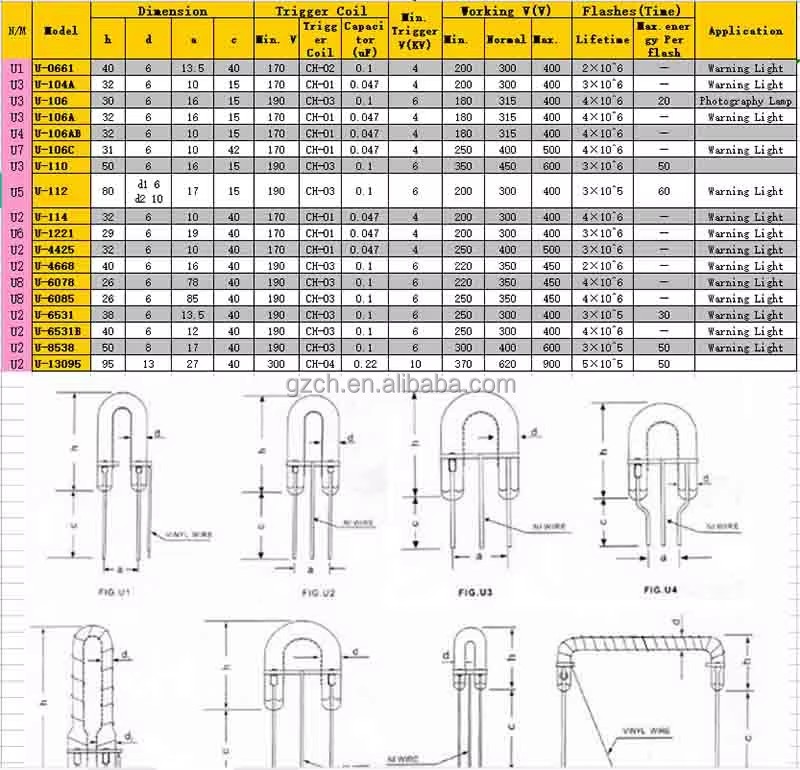

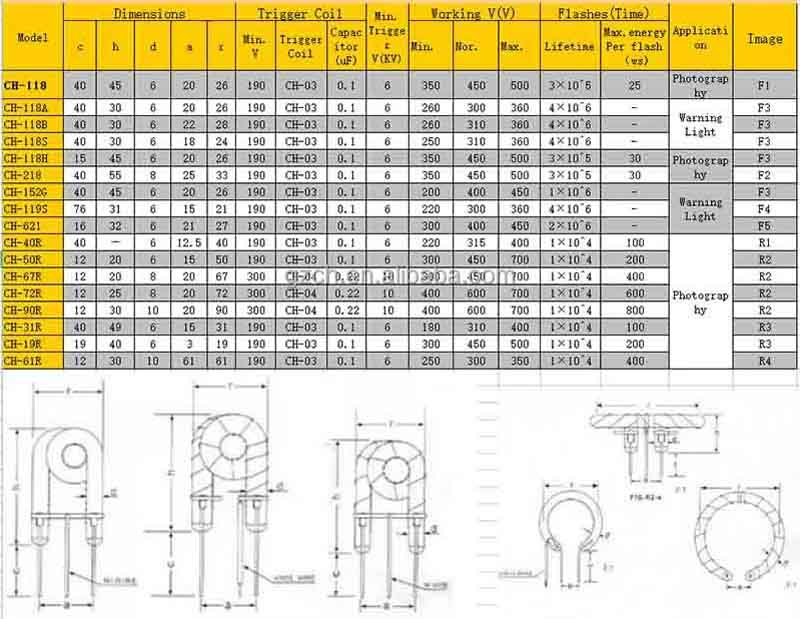

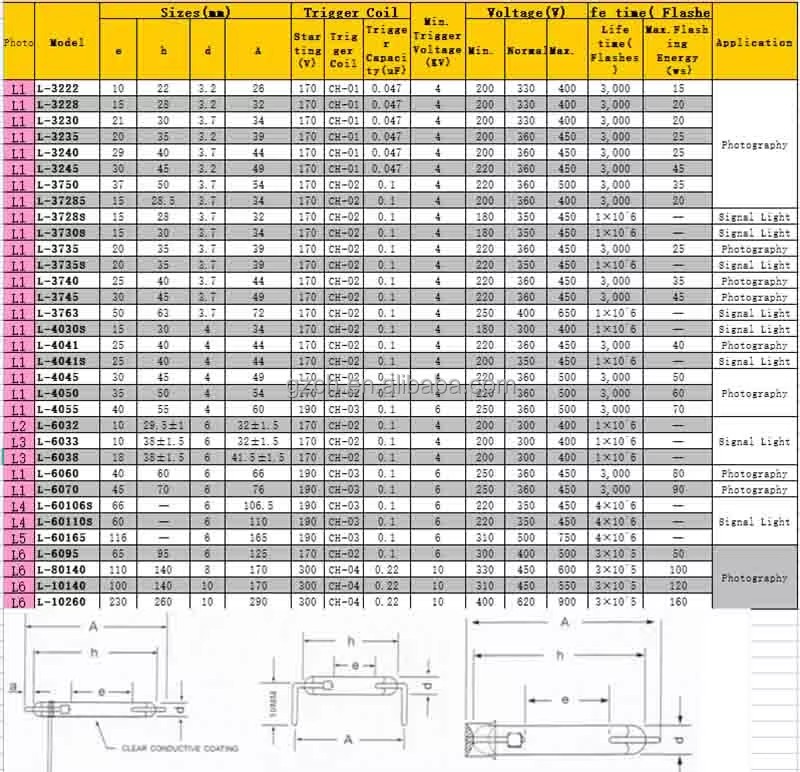

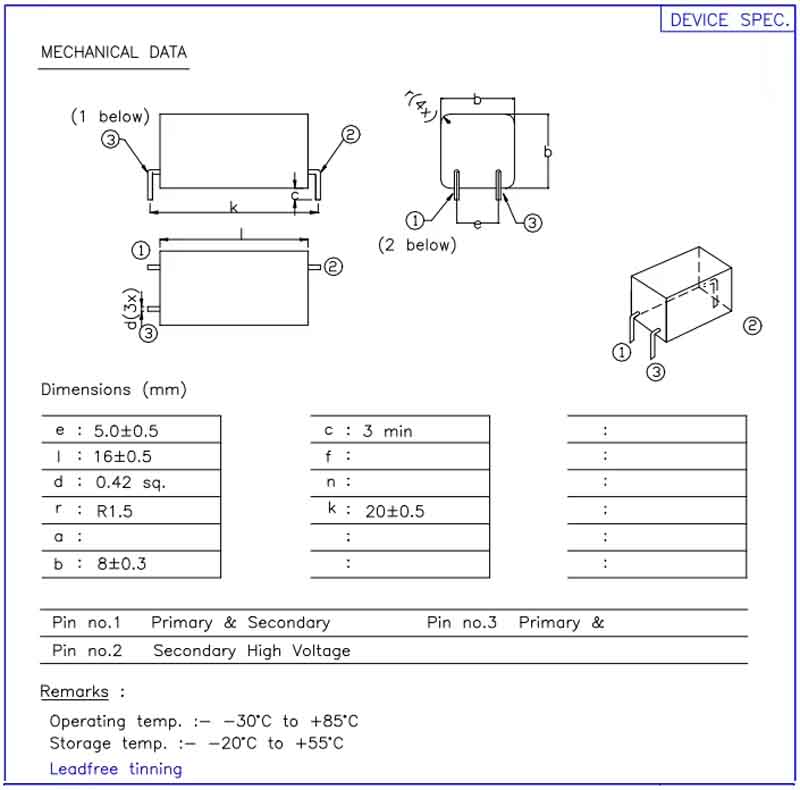

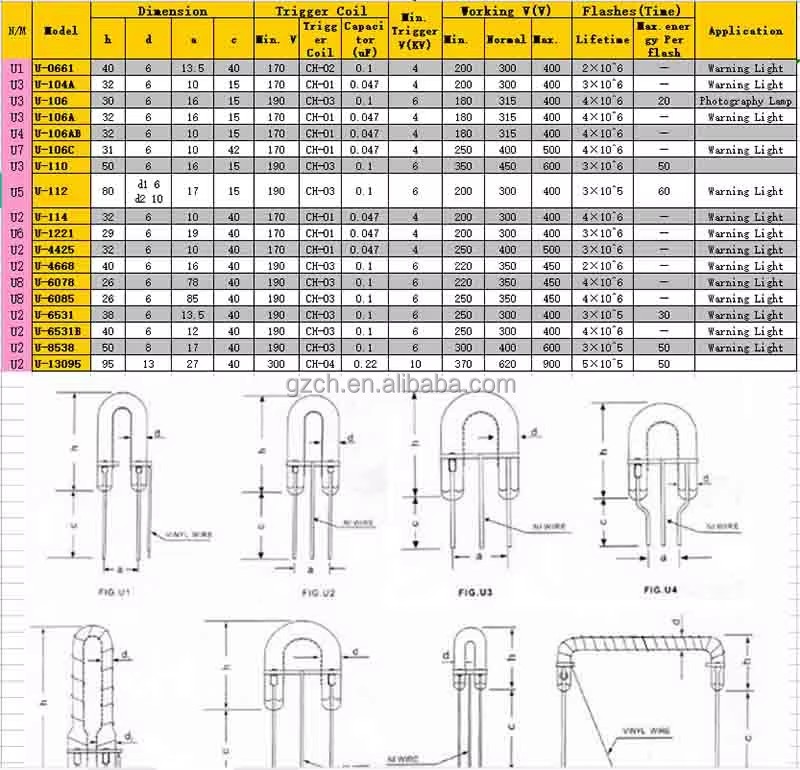

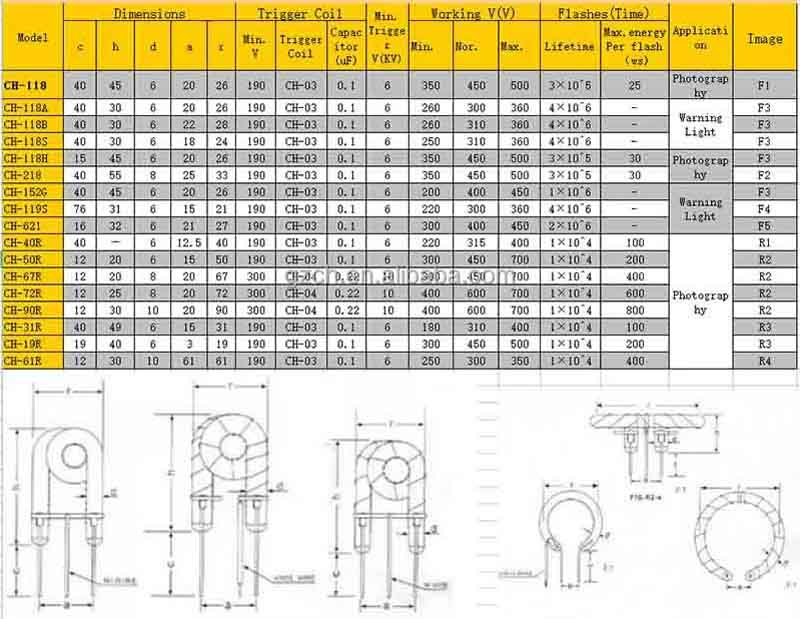

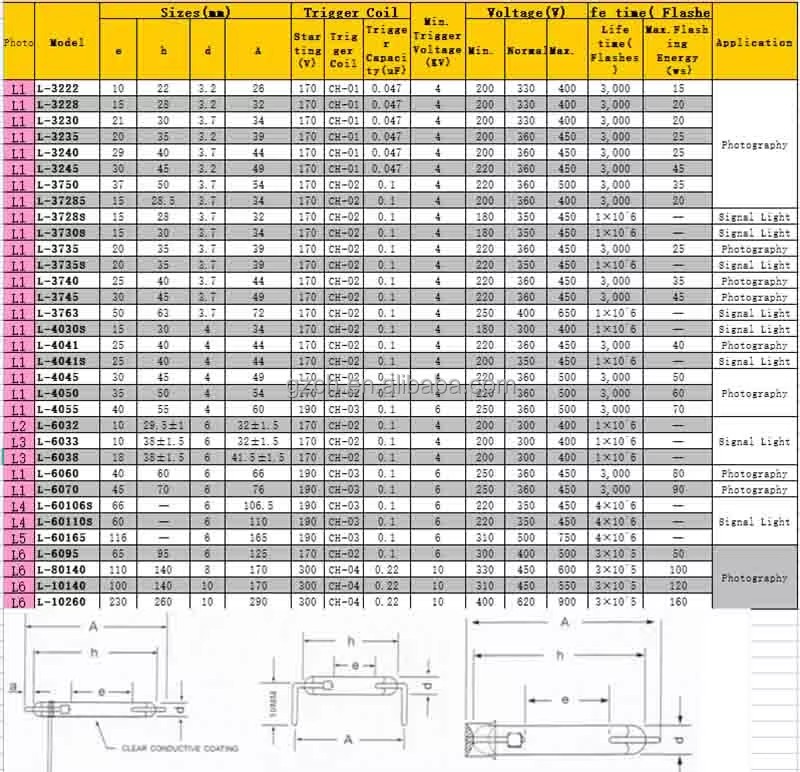

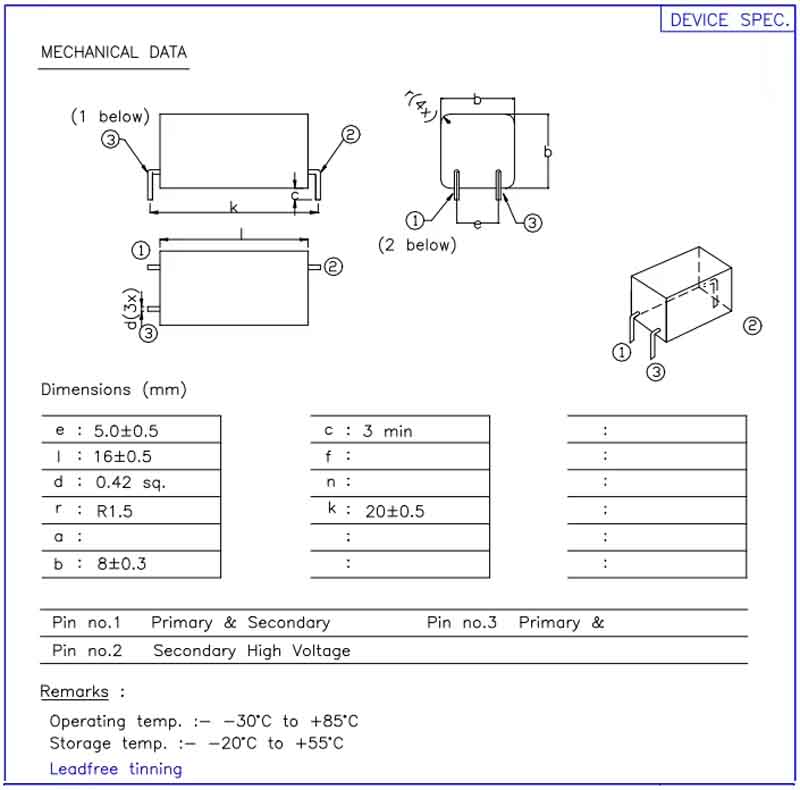

Shapes Available: Linear, U-shaped, Helical/Spiral, Circular/Ring, Door-shaped, and Special Geometry.

Customizable Dimensions: Diameter, arc length, electrode configuration tailored to your specifications.

Perfect for OEM Needs: Designed for private-label stroboscopes and warning light manufacturers.

How Xenon Flash Tubes Work (Technical Overview)

Trigger Pulse:

A high-voltage pulse ionizes the xenon gas inside the tube, starting the discharge process.

Energy Discharge:

The capacitor releases its stored energy once the gas becomes conductive, producing the flash.

Light Emission:

Excited xenon atoms emit an extremely bright flash, with high peak intensity, ensuring visibility even in difficult conditions.

Applications

Xenon flash tubes are widely used in various industries, including:

Industrial Stroboscopes & RPM Measurement

Traffic & Industrial Warning Beacons

Camera & Photographic Flash Systems

Aviation Obstruction & Aircraft Warning Lights

UV Sterilization & Insect Control Systems

Stage & Entertainment Lighting

Laser Pumping & Scientific Instruments

IPL Hair Removal & Beauty Devices

Laser Marking Machines

Large Industrial Printing Equipment

Technical Specifications (Typical)

Parameter Specification

Power Range 6 W / 15 W / 30 W up to 100 W

Tube Diameter 6 mm – 12 mm

Lifespan ≥ 10,000,000 flashes

Max. Anode Voltage 400 V

Nominal Anode Voltage 350 V

Min. Anode Voltage 220 V

Trigger Voltage 2 kV – 10 kV

Parameters can be customized to meet your circuit design needs.

Manufacturing & Quality Control

Precision Gas Filling Process: Ensures optimal performance and long lifespan.

Strict Electrode Alignment Control: Guarantees stability during high-frequency operations.

Aging Test Before Shipment: Ensures each tube meets high-performance standards.

Stable Batch-to-Batch Consistency: Ensures reliability across production runs, making them ideal for long-term supply projects.

OEM & Custom Support

We offer:

OEM/ODM Orders

Custom Dimensions & Shapes

Voltage & Lifetime Optimization

Bulk Supply for Stroboscope Manufacturers

Contact Us Today for:

Technical Consultation

Drawing Confirmation

Sample Support

Fast Quotat

High-Performance Xenon Flash Tubes for Stroboscopic, Warning & Industrial Applications

Reliable, High-Intensity Light Source for Precision Measurement, Safety, and Professional Use

Overview

We specialize in producing high-quality xenon flash tubes in various shapes, including linear, U-shaped, spiral, and circular designs, engineered for demanding applications across industries such as stroboscopic measurement, traffic and industrial warning lights, professional photography, aviation, scientific instruments, and more. These flash tubes provide high-intensity light output, fast response, and long lifespan, ensuring consistent performance even in extreme environments.

With over 25 years of manufacturing experience, we offer a reliable and cost-effective lighting solution for professionals worldwide, including lighting manufacturers, research institutes, laboratories, universities, and global wholesalers and retailers.

Core Product Features

Extremely Intense & Stable Light Output

White / Blue-White Light: Provides broad spectrum, ideal for freezing high-speed motion and ensuring accurate measurements.

High Peak Luminous Intensity: Ensures clear motion freezing for precise analysis.

Flash-to-Flash Consistency: Delivers reliable performance across multiple flashes, maintaining accuracy.

Fast Response for High-Speed Measurement

Microsecond to Millisecond Pulse Duration: Perfect for applications requiring rapid flashes, such as RPM measurement and vibration analysis.

Ideal for Motion Detection: Ensures precise measurement and inspection of high-speed motion.

Long Lifetime – Reduced Replacement Costs

≥ 10,000,000 Flashes: Designed for long operational life, significantly reducing maintenance and replacement costs.

Stable Electrode Structure: Optimized design ensures continuous operation for extended periods.

Wide Voltage Compatibility

Trigger Voltage: 2 kV – 10 kV.

Operating Voltage after Ionization: 200V – 600V, ensuring compatibility with most stroboscope power supplies.

Why Choose Xenon Flash Tubes?

Unmatched Peak Intensity

Xenon flash tubes can produce extremely high peak luminous intensity in a fraction of a millisecond, reaching megacandela (Mcd) levels. This intense pulse of light ensures superior visibility in fog, rain, snow, or even bright sunlight, making them ideal for emergency and industrial applications.

Simple Optics

The near-point-source characteristic of xenon flash tubes allows designers to use basic reflectors to achieve uniform 360° light coverage, making the design simpler and more cost-effective compared to LED systems, which require complex arrays and lenses.

Cost-Effective

Xenon flash tubes offer lower total costs than high-power LED arrays because they don’t require expensive heat dissipation systems or complex optical designs to achieve similar peak brightness.

Material Options – Tailored to Different Market Needs

Industrial Quartz / Fused Silica (Germany Origin)

High Thermal Resistance: Suitable for high-temperature environments.

Excellent UV Transmission: Ideal for professional, scientific, and heavy-duty applications.

Borosilicate Glass (Economic Solution)

Cost-Effective: Stable performance for standard industrial applications, making it perfect for budget-conscious projects.

Fully Customizable Designs (OEM Supported)

Shapes Available: Linear, U-shaped, Helical/Spiral, Circular/Ring, Door-shaped, and Special Geometry.

Customizable Dimensions: Diameter, arc length, electrode configuration tailored to your specifications.

Perfect for OEM Needs: Designed for private-label stroboscopes and warning light manufacturers.

How Xenon Flash Tubes Work (Technical Overview)

Trigger Pulse:

A high-voltage pulse ionizes the xenon gas inside the tube, starting the discharge process.

Energy Discharge:

The capacitor releases its stored energy once the gas becomes conductive, producing the flash.

Light Emission:

Excited xenon atoms emit an extremely bright flash, with high peak intensity, ensuring visibility even in difficult conditions.

Applications

Xenon flash tubes are widely used in various industries, including:

Industrial Stroboscopes & RPM Measurement

Traffic & Industrial Warning Beacons

Camera & Photographic Flash Systems

Aviation Obstruction & Aircraft Warning Lights

UV Sterilization & Insect Control Systems

Stage & Entertainment Lighting

Laser Pumping & Scientific Instruments

IPL Hair Removal & Beauty Devices

Laser Marking Machines

Large Industrial Printing Equipment

Technical Specifications (Typical)

Parameter Specification

Power Range 6 W / 15 W / 30 W up to 100 W

Tube Diameter 6 mm – 12 mm

Lifespan ≥ 10,000,000 flashes

Max. Anode Voltage 400 V

Nominal Anode Voltage 350 V

Min. Anode Voltage 220 V

Trigger Voltage 2 kV – 10 kV

Parameters can be customized to meet your circuit design needs.

Manufacturing & Quality Control

Precision Gas Filling Process: Ensures optimal performance and long lifespan.

Strict Electrode Alignment Control: Guarantees stability during high-frequency operations.

Aging Test Before Shipment: Ensures each tube meets high-performance standards.

Stable Batch-to-Batch Consistency: Ensures reliability across production runs, making them ideal for long-term supply projects.

OEM & Custom Support

We offer:

OEM/ODM Orders

Custom Dimensions & Shapes

Voltage & Lifetime Optimization

Bulk Supply for Stroboscope Manufacturers

Contact Us Today for:

Technical Consultation

Drawing Confirmation

Sample Support

Fast QuotationHigh-Performance Xenon Flash Tubes for Stroboscopic, Warning & Industrial Applications

Reliable, High-Intensity Light Source for Precision Measurement, Safety, and Professional Use

Overview

We specialize in producing high-quality xenon flash tubes in various shapes, including linear, U-shaped, spiral, and circular designs, engineered for demanding applications across industries such as stroboscopic measurement, traffic and industrial warning lights, professional photography, aviation, scientific instruments, and more. These flash tubes provide high-intensity light output, fast response, and long lifespan, ensuring consistent performance even in extreme environments.

With over 25 years of manufacturing experience, we offer a reliable and cost-effective lighting solution for professionals worldwide, including lighting manufacturers, research institutes, laboratories, universities, and global wholesalers and retailers.

Core Product Features

Extremely Intense & Stable Light Output

White / Blue-White Light: Provides broad spectrum, ideal for freezing high-speed motion and ensuring accurate measurements.

High Peak Luminous Intensity: Ensures clear motion freezing for precise analysis.

Flash-to-Flash Consistency: Delivers reliable performance across multiple flashes, maintaining accuracy.

Fast Response for High-Speed Measurement

Microsecond to Millisecond Pulse Duration: Perfect for applications requiring rapid flashes, such as RPM measurement and vibration analysis.

Ideal for Motion Detection: Ensures precise measurement and inspection of high-speed motion.

Long Lifetime – Reduced Replacement Costs

≥ 10,000,000 Flashes: Designed for long operational life, significantly reducing maintenance and replacement costs.

Stable Electrode Structure: Optimized design ensures continuous operation for extended periods.

Wide Voltage Compatibility

Trigger Voltage: 2 kV – 10 kV.

Operating Voltage after Ionization: 200V – 600V, ensuring compatibility with most stroboscope power supplies.

Why Choose Xenon Flash Tubes?

Unmatched Peak Intensity

Xenon flash tubes can produce extremely high peak luminous intensity in a fraction of a millisecond, reaching megacandela (Mcd) levels. This intense pulse of light ensures superior visibility in fog, rain, snow, or even bright sunlight, making them ideal for emergency and industrial applications.

Simple Optics

The near-point-source characteristic of xenon flash tubes allows designers to use basic reflectors to achieve uniform 360° light coverage, making the design simpler and more cost-effective compared to LED systems, which require complex arrays and lenses.

Cost-Effective

Xenon flash tubes offer lower total costs than high-power LED arrays because they don’t require expensive heat dissipation systems or complex optical designs to achieve similar peak brightness.

Material Options – Tailored to Different Market Needs

Industrial Quartz / Fused Silica (Germany Origin)

High Thermal Resistance: Suitable for high-temperature environments.

Excellent UV Transmission: Ideal for professional, scientific, and heavy-duty applications.

Borosilicate Glass (Economic Solution)

Cost-Effective: Stable performance for standard industrial applications, making it perfect for budget-conscious projects.

Fully Customizable Designs (OEM Supported)

Shapes Available: Linear, U-shaped, Helical/Spiral, Circular/Ring, Door-shaped, and Special Geometry.

Customizable Dimensions: Diameter, arc length, electrode configuration tailored to your specifications.

Perfect for OEM Needs: Designed for private-label stroboscopes and warning light manufacturers.

How Xenon Flash Tubes Work (Technical Overview)

Trigger Pulse:

A high-voltage pulse ionizes the xenon gas inside the tube, starting the discharge process.

Energy Discharge:

The capacitor releases its stored energy once the gas becomes conductive, producing the flash.

Light Emission:

Excited xenon atoms emit an extremely bright flash, with high peak intensity, ensuring visibility even in difficult conditions.

Applications

Xenon flash tubes are widely used in various industries, including:

Industrial Stroboscopes & RPM Measurement

Traffic & Industrial Warning Beacons

Camera & Photographic Flash Systems

Aviation Obstruction & Aircraft Warning Lights

UV Sterilization & Insect Control Systems

Stage & Entertainment Lighting

Laser Pumping & Scientific Instruments

IPL Hair Removal & Beauty Devices

Laser Marking Machines

Large Industrial Printing Equipment

Technical Specifications (Typical)

Parameter Specification

Power Range 6 W / 15 W / 30 W up to 100 W

Tube Diameter 6 mm – 12 mm

Lifespan ≥ 10,000,000 flashes

Max. Anode Voltage 400 V

Nominal Anode Voltage 350 V

Min. Anode Voltage 220 V

Trigger Voltage 2 kV – 10 kV

Parameters can be customized to meet your circuit design needs.

Manufacturing & Quality Control

Precision Gas Filling Process: Ensures optimal performance and long lifespan.

Strict Electrode Alignment Control: Guarantees stability during high-frequency operations.

Aging Test Before Shipment: Ensures each tube meets high-performance standards.

Stable Batch-to-Batch Consistency: Ensures reliability across production runs, making them ideal for long-term supply projects.

OEM & Custom Support

We offer:

OEM/ODM Orders

Custom Dimensions & Shapes

Voltage & Lifetime Optimization

Bulk Supply for Stroboscope Manufacturers

Contact Us Today for:

Technical Consultation

Drawing Confirmation

Sample Support

Fast Quotation

High-Performance Xenon Flash Tubes for Stroboscopic, Warning & Industrial Applications

Reliable, High-Intensity Light Source for Precision Measurement, Safety, and Professional Use

Overview

With world-class industrial design and manufacturing capabilities, we specialize in producing high-quality Xenon Flash Tubes in various shapes, including linear, U-shaped, spiral, and circular designs. Our tubes are meticulously engineered for demanding applications across diverse industries, such as stroboscopic instruments, warning beacon lights, traffic-violation cameras, professional photography, airport runway lighting, and solar simulation.

With over 25 years of manufacturing experience, we proudly serve thousands of customers worldwide, including professional lighting manufacturers, research institutes, laboratories, and universities. We provide a wide range of dimensions and trigger-control types, along with essential components such as trigger coils, transformers, and capacitors.

High-Performance Industrial-Grade Xenon Flash Lamp for Stroboscopes

Fast Trigger, Long Lifetime & OEM Replacement Solutions

In industrial stroboscopic and measurement applications, lighting performance is not defined by average brightness, but by peak intensity, timing precision, and spectral integrity.

For these critical requirements, xenon flash technology remains fundamentally irreplaceable by LED-based solutions.

This page provides a professional, engineering-level overview of why industrial-grade xenon flash lamps continue to serve as the reference light source for stroboscopes, RPM measurement systems, and high-speed inspection environments worldwide.

1. Ultra-High Peak Intensity – Beyond the Physical Limits of LEDs

Xenon flash lamps generate extremely high peak luminous intensity within microsecond-to-millisecond pulses by rapidly discharging stored capacitor energy through ionized xenon gas.

Peak brightness can be 10–100 times higher than high-power LEDs at comparable pulse durations

Enables clear visibility on large, dark, or fast-moving objects

Ideal for stroboscopic observation, motion freezing, and high-speed measurement

Why LEDs cannot replace xenon:

LEDs are constrained by semiconductor junction temperature and current density. Attempting to achieve similar peak output results in rapid thermal degradation or device failure.

2. Fast Trigger Response & Microsecond-Level Stop-Motion Capability

The flash duration of a xenon lamp is a pure physical discharge process, not limited by electronic driver switching speed.

Typical T₀.₅ (half-power width): 1–5 microseconds

Delivers exceptionally sharp frozen images of:

Turbine blades

High-speed rollers

Ultra-high RPM rotating shafts

In contrast, industrial LED systems suffer from:

Driver latency

Current rise-time limitations

Timing jitter at high frequencies

This makes xenon the preferred solution for precision RPM measurement, phase alignment, and vibration analysis.

3. Stable Flash Output Across Wide Operating Frequencies

Xenon flash lamps maintain consistent light output from single-shot flashes to high-frequency repetitive operation.

No thermal roll-off during short, high-energy pulses

Uniform brightness across varying repetition rates

Reliable performance in continuous industrial duty cycles

LED systems typically experience output instability or brightness decay under equivalent pulsed-load conditions.

4. High Joule Energy Per Pulse for Long-Range & Large-Scale Illumination

Industrial xenon flash lamps support high joule-level energy discharge, enabling:

Long-distance illumination

Wide-area inspection coverage

Effective lighting through contaminated air paths

This capability is essential for steel sheet inspection, large printing presses, and production-line monitoring, where LED strobes lack sufficient penetration and coverage.

5. Deep Penetration in Harsh Industrial Environments

Many industrial facilities contain oil mist, steam, dust, smoke, or airborne fibers, such as:

Paper mills

Textile plants

Steel processing lines

Chemical and petrochemical facilities

Thanks to its high peak radiant power, xenon light penetrates atmospheric interference more effectively than LED illumination, maintaining:

High contrast

Clear edge definition

Reliable visual and camera-based observation

6. Broad-Spectrum White Light with True Color Rendering

Xenon flash lamps emit continuous broadband white light closely resembling natural daylight.

CRI near 100

No spectral gaps

Accurate color perception of markings, surfaces, and defects

LED systems, based on narrow-band emission or phosphor conversion, may introduce spectral distortion, affecting inspection accuracy.

7. Electrical & Electromagnetic Robustness (EMC Advantage)

Although xenon lamps require a high-voltage trigger pulse, the lamp itself is:

A simple gas-filled quartz tube

Free of semiconductor junctions

Immune to thermal runaway and latch-up

This provides exceptional reliability in environments with:

Strong electromagnetic interference (EMI)

Electrical noise

Unstable power conditions

Ionizing radiation exposure

8. Predictable End-of-Life & Reduced Maintenance Risk

Unlike LEDs, which may fail suddenly, xenon flash lamps typically exhibit gradual end-of-life behavior, such as:

Reduced flash intensity

Occasional misfiring at high repetition rates

This allows for planned preventive maintenance, minimizing unexpected downtime in critical industrial systems.

9. Modular OEM Replacement & System Compatibility

Industrial xenon flash lamps are available in multiple configurations, including:

Linear

U-shaped

Spiral

Circular

They are designed for plug-and-play replacement in most legacy and modern stroboscope systems, offering:

Fast servicing

Lower lifecycle cost

Full compatibility with existing power supplies

Replacing a xenon tube is often significantly simpler and more economical than repairing high-power LED arrays with complex cooling and driver electronics.

10. Industrial Application Matrix

Application Key Requirement Why Xenon Is Preferred

High-Speed Printing High contrast & true color Accurate CMYK registration without color shift

Vibration Analysis Microsecond timing Jitter-free phase synchronization

Large-Scale Inspection Long-range illumination High joule output over wide areas

Automotive Crash Testing Massive light intensity Overpowers ambient light for high-speed cameras

Engineering Conclusion

For industrial applications demanding extreme peak brightness, microsecond-level timing precision, broadband spectral output, and long-term reliability in harsh environments, xenon flash lamps remain the undisputed reference technology—well beyond the physical limits of LED-based solutions.

High-Performance Industrial-Grade Xenon Flash Lamp for Stroboscopes

Fast Trigger, Long Lifetime & OEM Replacement Solutions

In industrial stroboscopic and measurement applications, lighting performance is not defined by average brightness, but by peak intensity, timing precision, and spectral integrity.

For these critical requirements, xenon flash technology remains fundamentally irreplaceable by LED-based solutions.

This page provides a professional, engineering-level overview of why industrial-grade xenon flash lamps continue to serve as the reference light source for stroboscopes, RPM measurement systems, and high-speed inspection environments worldwide.

1. Ultra-High Peak Intensity – Beyond the Physical Limits of LEDs

Xenon flash lamps generate extremely high peak luminous intensity within microsecond-to-millisecond pulses by rapidly discharging stored capacitor energy through ionized xenon gas.

Peak brightness can be 10–100 times higher than high-power LEDs at comparable pulse durations

Enables clear visibility on large, dark, or fast-moving objects

Ideal for stroboscopic observation, motion freezing, and high-speed measurement

Why LEDs cannot replace xenon:

LEDs are constrained by semiconductor junction temperature and current density. Attempting to achieve similar peak output results in rapid thermal degradation or device failure.

2. Fast Trigger Response & Microsecond-Level Stop-Motion Capability

The flash duration of a xenon lamp is a pure physical discharge process, not limited by electronic driver switching speed.

Typical T₀.₅ (half-power width): 1–5 microseconds

Delivers exceptionally sharp frozen images of:

Turbine blades

High-speed rollers

Ultra-high RPM rotating shafts

In contrast, industrial LED systems suffer from:

Driver latency

Current rise-time limitations

Timing jitter at high frequencies

This makes xenon the preferred solution for precision RPM measurement, phase alignment, and vibration analysis.

3. Stable Flash Output Across Wide Operating Frequencies

Xenon flash lamps maintain consistent light output from single-shot flashes to high-frequency repetitive operation.

No thermal roll-off during short, high-energy pulses

Uniform brightness across varying repetition rates

Reliable performance in continuous industrial duty cycles

LED systems typically experience output instability or brightness decay under equivalent pulsed-load conditions.

4. High Joule Energy Per Pulse for Long-Range & Large-Scale Illumination

Industrial xenon flash lamps support high joule-level energy discharge, enabling:

Long-distance illumination

Wide-area inspection coverage

Effective lighting through contaminated air paths

This capability is essential for steel sheet inspection, large printing presses, and production-line monitoring, where LED strobes lack sufficient penetration and coverage.

5. Deep Penetration in Harsh Industrial Environments

Many industrial facilities contain oil mist, steam, dust, smoke, or airborne fibers, such as:

Paper mills

Textile plants

Steel processing lines

Chemical and petrochemical facilities

Thanks to its high peak radiant power, xenon light penetrates atmospheric interference more effectively than LED illumination, maintaining:

High contrast

Clear edge definition

Reliable visual and camera-based observation

6. Broad-Spectrum White Light with True Color Rendering

Xenon flash lamps emit continuous broadband white light closely resembling natural daylight.

CRI near 100

No spectral gaps

Accurate color perception of markings, surfaces, and defects

LED systems, based on narrow-band emission or phosphor conversion, may introduce spectral distortion, affecting inspection accuracy.

7. Electrical & Electromagnetic Robustness (EMC Advantage)

Although xenon lamps require a high-voltage trigger pulse, the lamp itself is:

A simple gas-filled quartz tube

Free of semiconductor junctions

Immune to thermal runaway and latch-up

This provides exceptional reliability in environments with:

Strong electromagnetic interference (EMI)

Electrical noise

Unstable power conditions

Ionizing radiation exposure

8. Predictable End-of-Life & Reduced Maintenance Risk

Unlike LEDs, which may fail suddenly, xenon flash lamps typically exhibit gradual end-of-life behavior, such as:

Reduced flash intensity

Occasional misfiring at high repetition rates

This allows for planned preventive maintenance, minimizing unexpected downtime in critical industrial systems.

9. Modular OEM Replacement & System Compatibility

Industrial xenon flash lamps are available in multiple configurations, including:

Linear

U-shaped

Spiral

Circular

They are designed for plug-and-play replacement in most legacy and modern stroboscope systems, offering:

Fast servicing

Lower lifecycle cost

Full compatibility with existing power supplies

Replacing a xenon tube is often significantly simpler and more economical than repairing high-power LED arrays with complex cooling and driver electronics.

10. Industrial Application Matrix

Application Key Requirement Why Xenon Is Preferred

High-Speed Printing High contrast & true color Accurate CMYK registration without color shift

Vibration Analysis Microsecond timing Jitter-free phase synchronization

Large-Scale Inspection Long-range illumination High joule output over wide areas

Automotive Crash Testing Massive light intensity Overpowers ambient light for high-speed cameras

Engineering Conclusion

For industrial applications demanding extreme peak brightness, microsecond-level timing precision, broadband spectral output, and long-term reliability in harsh environments, xenon flash lamps remain the undisputed reference technology—well beyond the physical limits of LED-based solutions.

Product Detail: Industrial-Grade Xenon Flash Lamp for High-Speed Stroboscopes

The Professional Choice for Motion Analysis & RPM Measurement

In industrial stroboscopic applications, performance is defined by peak intensity, timing precision, and spectral integrity. While LED technology has advanced, Xenon flash technology remains fundamentally irreplaceable for critical high-speed requirements.

Core Features & Technical Advantages

1. Ultra-High Peak Intensity – Beyond the Physical Limits of LEDs

Xenon flash lamps generate extremely high peak luminous intensity by rapidly discharging stored capacitor energy through ionized xenon gas.1

● Performance: Peak brightness can be 10–100 times higher than high-power LEDs.

● Benefit: Enables clear visibility on large, dark, or fast-moving objects.

● The Science: LEDs are constrained by semiconductor junction temperature; xenon handles massive energy spikes without thermal degradation.

2. Microsecond-Level Stop-Motion Capability

The flash duration is a pure physical discharge process, not limited by electronic driver switching speed.

● Precision: Typical $T_{0.5}$ (half-power width) of 1–5 microseconds.

● Clarity: Delivers exceptionally sharp frozen images of turbine blades, high-speed rollers, and ultra-high RPM shafts.

● Advantage: Eliminates the driver latency and timing jitter common in LED systems.

3. Stable Output Across Wide Operating Frequencies

Consistent light output from single-shot flashes to high-frequency repetitive operation.

● No Thermal Roll-off: Maintains uniform brightness across varying repetition rates.

● Industrial Duty: Reliable performance in continuous 24/7 industrial duty cycles without the output decay seen in pulsed LED loads.

4. High Joule Energy for Large-Scale Illumination

Supports high joule-level energy discharge for demanding environments.

● Coverage: Enables long-distance illumination and wide-area inspection.

● Efficiency: Essential for steel sheet inspection and large printing presses where LED strobes lack sufficient penetration.

5. Deep Penetration in Harsh Industrial Environments

Specifically engineered for facilities containing oil mist, steam, dust, or smoke (e.g., paper mills, textile plants, and chemical facilities).

● Visibility: High peak radiant power penetrates atmospheric interference more effectively than LEDs.

● Result: Maintains high contrast and clear edge definition for both visual and camera-based observation.

6. True Color Rendering (Broad-Spectrum White Light)

Emits continuous broadband white light closely resembling natural daylight.

● Accuracy: CRI near 100 with no spectral gaps.

● Inspection: Crucial for accurate color perception of markings and surface defects that narrow-band LEDs may distort.2

7. Electrical & Electromagnetic Robustness (EMC)

The lamp is a simple gas-filled quartz tube free of semiconductor junctions.

● Reliability: Immune to thermal runaway, latch-up, and strong electromagnetic interference (EMI).

● Environment: Performs reliably in areas with high electrical noise or ionizing radiation.

8. Predictable End-of-Life & Maintenance

Xenon lamps exhibit gradual "wear-out" behavior rather than sudden catastrophic failure.

● Early Warning: Indicators like reduced intensity or occasional misfiring allow for planned preventive maintenance.

● Uptime: Minimizes unexpected downtime in critical production lines.

9. Modular OEM Replacement & System Compatibility

Available in Linear, U-shaped, Spiral, and Circular configurations.

● Plug-and-Play: Designed for most legacy and modern stroboscope systems.

● Cost-Effective: Replacing a xenon tube is significantly simpler and more economical than repairing complex LED arrays and cooling electronics.

10. Industrial Application Matrix

|

Application

|

Key Requirement

|

Why Xenon Is Preferred

|

|

High-Speed Printing

|

High contrast & true color

|

Accurate CMYK registration without color shift

|

|

Vibration Analysis

|

Microsecond timing

|

Jitter-free phase synchronization

|

|

Large-Scale Inspection

|

Long-range illumination

|

High joule output over wide areas

|

|

Automotive Crash Testing

|

Massive light intensity

|

Overpowers ambient light for high-speed cameras

|

Engineering Conclusion

For applications demanding extreme peak brightness, microsecond timing precision, and long-term reliability in harsh environments, Xenon flash lamps remain the undisputed reference technology.

Our current models for your reference:

High-Performance Industrial-Grade Xenon Flash Lamp for Stroboscopes

Fast Trigger, Long Lifetime & OEM Replacement Solutions

In industrial stroboscopic and measurement applications, lighting performance is not defined by average brightness, but by peak intensity, timing precision, and spectral integrity.

For these critical requirements, xenon flash technology remains fundamentally irreplaceable by LED-based solutions.

This page provides a professional, engineering-level overview of why industrial-grade xenon flash lamps continue to serve as the reference light source for stroboscopes, RPM measurement systems, and high-speed inspection environments worldwide.

1. Ultra-High Peak Intensity – Beyond the Physical Limits of LEDs

Xenon flash lamps generate extremely high peak luminous intensity within microsecond-to-millisecond pulses by rapidly discharging stored capacitor energy through ionized xenon gas.

Peak brightness can be 10–100 times higher than high-power LEDs at comparable pulse durations

Enables clear visibility on large, dark, or fast-moving objects

Ideal for stroboscopic observation, motion freezing, and high-speed measurement

Why LEDs cannot replace xenon:

LEDs are constrained by semiconductor junction temperature and current density. Attempting to achieve similar peak output results in rapid thermal degradation or device failure.

2. Fast Trigger Response & Microsecond-Level Stop-Motion Capability

The flash duration of a xenon lamp is a pure physical discharge process, not limited by electronic driver switching speed.

Typical T₀.₅ (half-power width): 1–5 microseconds

Delivers exceptionally sharp frozen images of:

Turbine blades

High-speed rollers

Ultra-high RPM rotating shafts

In contrast, industrial LED systems suffer from:

Driver latency

Current rise-time limitations

Timing jitter at high frequencies

This makes xenon the preferred solution for precision RPM measurement, phase alignment, and vibration analysis.

3. Stable Flash Output Across Wide Operating Frequencies

Xenon flash lamps maintain consistent light output from single-shot flashes to high-frequency repetitive operation.

No thermal roll-off during short, high-energy pulses

Uniform brightness across varying repetition rates

Reliable performance in continuous industrial duty cycles

LED systems typically experience output instability or brightness decay under equivalent pulsed-load conditions.

4. High Joule Energy Per Pulse for Long-Range & Large-Scale Illumination

Industrial xenon flash lamps support high joule-level energy discharge, enabling:

Long-distance illumination

Wide-area inspection coverage

Effective lighting through contaminated air paths

This capability is essential for steel sheet inspection, large printing presses, and production-line monitoring, where LED strobes lack sufficient penetration and coverage.

5. Deep Penetration in Harsh Industrial Environments

Many industrial facilities contain oil mist, steam, dust, smoke, or airborne fibers, such as:

Paper mills

Textile plants

Steel processing lines

Chemical and petrochemical facilities

Thanks to its high peak radiant power, xenon light penetrates atmospheric interference more effectively than LED illumination, maintaining:

High contrast

Clear edge definition

Reliable visual and camera-based observation

6. Broad-Spectrum White Light with True Color Rendering

Xenon flash lamps emit continuous broadband white light closely resembling natural daylight.

CRI near 100

No spectral gaps

Accurate color perception of markings, surfaces, and defects

LED systems, based on narrow-band emission or phosphor conversion, may introduce spectral distortion, affecting inspection accuracy.

7. Electrical & Electromagnetic Robustness (EMC Advantage)

Although xenon lamps require a high-voltage trigger pulse, the lamp itself is:

A simple gas-filled quartz tube

Free of semiconductor junctions

Immune to thermal runaway and latch-up

This provides exceptional reliability in environments with:

Strong electromagnetic interference (EMI)

Electrical noise

Unstable power conditions

Ionizing radiation exposure

8. Predictable End-of-Life & Reduced Maintenance Risk

Unlike LEDs, which may fail suddenly, xenon flash lamps typically exhibit gradual end-of-life behavior, such as:

Reduced flash intensity

Occasional misfiring at high repetition rates

This allows for planned preventive maintenance, minimizing unexpected downtime in critical industrial systems.

9. Modular OEM Replacement & System Compatibility

Industrial xenon flash lamps are available in multiple configurations, including:

Linear

U-shaped

Spiral

Circular

They are designed for plug-and-play replacement in most legacy and modern stroboscope systems, offering:

Fast servicing

Lower lifecycle cost

Full compatibility with existing power supplies

Replacing a xenon tube is often significantly simpler and more economical than repairing high-power LED arrays with complex cooling and driver electronics.

10. Industrial Application Matrix

Application Key Requirement Why Xenon Is Preferred

High-Speed Printing High contrast & true color Accurate CMYK registration without color shift

Vibration Analysis Microsecond timing Jitter-free phase synchronization

Large-Scale Inspection Long-range illumination High joule output over wide areas

Automotive Crash Testing Massive light intensity Overpowers ambient light for high-speed cameras

Engineering Conclusion

For industrial applications demanding extreme peak brightness, microsecond-level timing precision, broadband spectral output, and long-term reliability in harsh environments, xenon flash lamps remain the undisputed reference technology—well beyond the physical limits of LED-based solutions.

Key Features & Technical Advantages

1. Ultra-High Peak Intensity (LED Overpowering)

Xenon technology delivers luminous intensity that LEDs simply cannot match. Within microsecond pulses, Xenon lamps produce brightness 10–100× higher than high-power LEDs.

The Result: Perfect "motion freezing" of ultra-fast rotating machinery.

The Science: Unlike LEDs, which suffer from thermal damage at high current densities, Xenon gas ionization handles massive energy spikes effortlessly.

2. Microsecond Precision & Zero-Jitter Timing

Triggered by a high-voltage pulse (2–10 kV), our lamps ensure rapid gas ionization with timing accuracy in the microsecond range.

Application: Critical for RPM measurement, phase alignment, and rotational analysis.

Advantage: Eliminates the driver latency and current rise-time "jitter" common in LED systems.

3. Broad-Spectrum "Daylight" Output

Emits a continuous broadband white light (5500K–6500K) that mimics natural daylight.

True Color Rendering: No spectral gaps. Essential for inspecting printing quality, textile defects, and surface coatings where color accuracy is vital.

Visual Comfort: Provides superior contrast for the human eye compared to phosphor-converted LED light.

4. Industrial-Grade Robustness

Thermal Stability: No semiconductor junction means no thermal runaway. The output remains stable across wide frequency ranges without "thermal roll-off."

Environmental Resilience: Higher penetration through oil mist, steam, and dust—common in paper and steel mills.

Technical Comparison: Xenon vs. LED

Feature Xenon Flash Lamp (Industrial) High-Power LED Strobe

Peak Brightness Extreme (10-100x higher) Limited by junction heat

Flash Duration Ultra-short (1–5μs T0.5) Limited by driver rise time

Color Spectrum Continuous (CRI ~100) Narrow-band (Potential gaps)

Thermal Decay None (Gas-based discharge) Significant at high frequencies

Maintenance Plug-and-play tube replacement Complex board-level repair

导出到 Google 表格

Industrial Application Matrix

High-Speed Printing: Ensures accurate registration of CMYK marks at full press speed.

RPM & Rotational Measurement: Provides the precision required for laboratory-grade strobe tachometers.

Metals & Paper Inspection: High-energy pulses provide clear visibility on wide, fast-moving webs.

Motion Analysis: Ideal for high-speed photography and synchronization in R&D environments.

Why Choose Our Xenon Solutions?

Ultra-Long Service Life: Rated for millions to tens of millions of flashes with minimal degradation.

OEM Replacement Ready: Available in Linear, U-shaped, Spiral, and Circular configurations to fit legacy and modern power supplies.

Proven Reliability: The industry reference standard where timing and brightness are non-negotiable.Key Features & Technical Advantages

1. Ultra-High Peak Intensity (LED Overpowering)

Xenon technology delivers luminous intensity that LEDs simply cannot match. Within microsecond pulses, Xenon lamps produce brightness 10–100× higher than high-power LEDs.

The Result: Perfect "motion freezing" of ultra-fast rotating machinery.

The Science: Unlike LEDs, which suffer from thermal damage at high current densities, Xenon gas ionization handles massive energy spikes effortlessly.

2. Microsecond Precision & Zero-Jitter Timing

Triggered by a high-voltage pulse (2–10 kV), our lamps ensure rapid gas ionization with timing accuracy in the microsecond range.

Application: Critical for RPM measurement, phase alignment, and rotational analysis.

Advantage: Eliminates the driver latency and current rise-time "jitter" common in LED systems.

3. Broad-Spectrum "Daylight" Output

Emits a continuous broadband white light (5500K–6500K) that mimics natural daylight.

True Color Rendering: No spectral gaps. Essential for inspecting printing quality, textile defects, and surface coatings where color accuracy is vital.

Visual Comfort: Provides superior contrast for the human eye compared to phosphor-converted LED light.

4. Industrial-Grade Robustness

Thermal Stability: No semiconductor junction means no thermal runaway. The output remains stable across wide frequency ranges without "thermal roll-off."

Environmental Resilience: Higher penetration through oil mist, steam, and dust—common in paper and steel mills.

Technical Comparison: Xenon vs. LED

Feature Xenon Flash Lamp (Industrial) High-Power LED Strobe

Peak Brightness Extreme (10-100x higher) Limited by junction heat

Flash Duration Ultra-short (1–5μs T0.5) Limited by driver rise time

Color Spectrum Continuous (CRI ~100) Narrow-band (Potential gaps)

Thermal Decay None (Gas-based discharge) Significant at high frequencies

Maintenance Plug-and-play tube replacement Complex board-level repair

导出到 Google 表格

Industrial Application Matrix

High-Speed Printing: Ensures accurate registration of CMYK marks at full press speed.

RPM & Rotational Measurement: Provides the precision required for laboratory-grade strobe tachometers.

Metals & Paper Inspection: High-energy pulses provide clear visibility on wide, fast-moving webs.

Motion Analysis: Ideal for high-speed photography and synchronization in R&D environments.

Why Choose Our Xenon Solutions?

Ultra-Long Service Life: Rated for millions to tens of millions of flashes with minimal degradation.

OEM Replacement Ready: Available in Linear, U-shaped, Spiral, and Circular configurations to fit legacy and modern power supplies.

Proven Reliability: The industry reference standard where timing and brightness are non-negotiable.